Pipeline Inspections

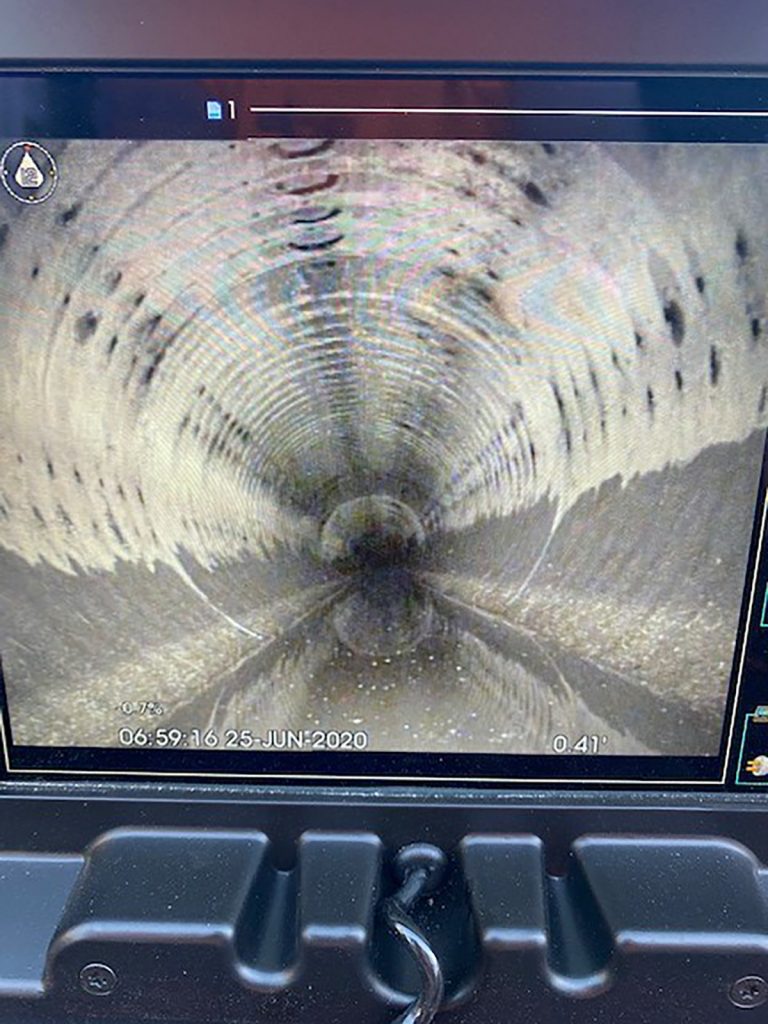

We utilize state-of-the-art video inspection equipment to perform closed circuit video inspection of virtually all diameters of sewer, stormwater, culvert, potable water, and industrial pipeline systems.

We can find...

dips, offset joints, cracks, roots, blockages, and infiltration problems

Video inspection is invaluable for the identification and documentation of deficiencies such as dips, offset joints, cracks, roots, blockages, infiltration, and more. Accurate assessment of pipeline condition can help prevent faulty installations, predict potential failure points, and identify deficiencies in need of repair.

types of inspections

- Preliminary – Conducted immediately after installation by contractor or owner to verify the initial construction of pipeline so that any outstanding deficiencies may be resolved prior to submital for acceptance by the owner.

- Final – Conducted to document the final condition of pipeline installations as submitted for owner and governmental acceptance. Final inspections are commonly performed with a governmental inspector or CEI (construction engineering and inspection representative) in attendance.

- Maintenance – Conducted periodically to assess the condition of aging pipelines, identify potential failure points, and investigate deficiencies in need of immediate repair.

- Investigatory – Conducted to determine the composition of the system; often when plans have been lost or are unavailable. A radio beacon can be attached to camera equipment to aid in mapping the system from the surface.

Push Camera

Suitable for inspecting pipelines as small as 1″ in diameter, our industrial push cameras are used to inspect pipeline otherwise unsuitable for crawler camera use. Our push cameras feature self-leveling camera heads, footage counters, and integrate seamlessly with our Video Inspection Trucks to provide digital recording and fully detailed reporting.

Crawler Camera

Typically deployed in pipelines that are 6″ in diameter and larger. Robotic crawler cameras are connected to specialized video inspection trucks by an umbilical cable and can traverse over 1,000 feet of pipeline in a single run. Once deployed, the operator controls the entire process from a control room on the truck.